Cascade Biocatalysts Secures $2.6 M to Scale Enzymes for Biomanufacturing

Published by Todd Bush on August 22, 2023

August 22, 2023 09:13 AM Eastern Daylight Time

DENVER--(BUSINESS WIRE)--Cascade Biocatalysts, a biomanufacturing company catalyzing green chemistry, raised an oversubscribed $2.6 M pre-seed led by Ten VC with participation from mplify.LA, Boost VC, Range Ventures, Spacecadet, and the Cool Climate Collective. Cascade aims to use the raised funds to scale its impact from the lab bench to pilot scale and to support its initial wave of customers.

Cascade's co-founders: Alex Rosay (CEO, left) and James Weltz (CSO, right)

Cascade’s vision is to make the industrial use of enzymes more affordable to accelerate the transition to greener chemical manufacturing. At the heart of Cascade Biocatalysts' breakthrough lies its proprietary technology, the patent-pending Body Armor for Enzymes™, which drives more cost-effective and sustainable chemical reactions by improving enzyme performance.

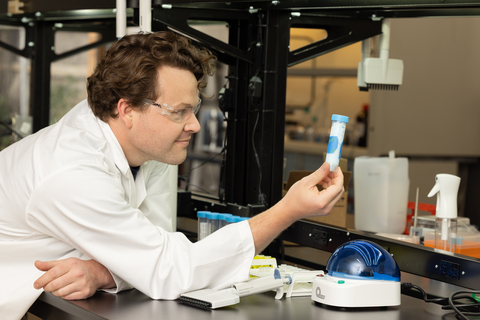

The inventor and his creation: James Weltz, Cascade's CSO, with his novel enzyme immobilization solution

For billions of years, nature has relied on enzymes to efficiently make useful molecules. Cascade is moving nature's catalysts out of the cell and into the factory, transitioning chemical manufacturing away from energy-intensive, petrochemical-based processes. By doing so, the company aims to address the three gigatons of greenhouse gas emissions generated by the chemicals industry. Overcoming the current barrier of enzyme cost is a crucial step toward making this a reality.

Cascade’s technology uses readily available and cost-effective materials to keep expensive enzymes lasting significantly longer. So far, Cascade has worked on 15 different enzymes and is 100% successful at improving stability under tough industrial conditions, including for multiple paying customers at the lab scale. Find more data in this article that highlights Cascade’s potential in creating molecular factories. The company's initial projects span diverse applications, including carbon dioxide capture, fragrance manufacturing, and wastewater treatment, highlighting the broad commercial potential of biocatalysts.

The company's co-founders, Alex Rosay and James Weltz, bring together chemical engineering backgrounds, industry expertise, and scientific innovation.

James invented the technology while doing his PhD in the field of enzyme immobilization. “I had tried all other solutions, and they were inconsistent,” said James Weltz, Cascade’s Chief Scientific Officer (CSO). “When I developed our novel approach, I transformed immobilizing enzymes from a trial-and-error process into an engineering discipline.”

“From the moment I met James, I knew his technology would revolutionize biomanufacturing,” said Alex Rosay, CEO and industry veteran. “From my time as a product manager at Zymergen, I saw a billion dollars go towards precision fermentation unsuccessfully, and I realized cell-free and enzyme processes were the future of the industry, though too expensive today. James’s technology solves this.”

With its headquarters in Denver and a presence in California and New York, Cascade Biocatalysts is well-positioned to spearhead the cell-free biomanufacturing revolution. Interested parties can contact Alex Rosay at alex@cascadebiocatalysts.com to learn more.

>> In Other News: Astronergy, NIO and OPF hand for the world's first EV PV Self-consumption System with V2G Chargers at Qilian Mountain National Park

About Cascade Biocatalysts

Cascade Biocatalysts specializes in advancing enzyme-based processes. With its groundbreaking Body Armor for Enzymes™ technology, the company seeks to drive greener and more cost-effective chemical reactions, reducing greenhouse gas emissions and promoting sustainability across industries. Headquartered in Denver, Cascade is committed to scaling up its impact and revolutionizing the future of the chemical economy.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

Can Cement Save the Coast? Pegasus Thinks So

Inside This Issue 🏝️ Pegasus Capital Advisors and Partanna Collaborate to Scale Carbon-Negative Cement for Coastal Resilience 🌾 Scaling Carbon Sequestration with Precision: How Charm Industrial Us...

-

Game-Changer? New Bill Tackles Wildfires & Carbon

Inside This Issue 🔥 Whitehouse, Schiff Introduce Bill to Reduce Wildfire Risk with Innovative Carbon Removal Solutions ⚡ Plug Power and Allied Green Expand Strategic Collaboration with New 2 GW El...

-

Ballard’s $1.5M Engine Deal Could Change Rail Forever

Inside This Issue 🚂 Ballard Announces 1.5 MW Fuel Cell Engine Order for Sierra Northern Railway 🌊 Sonardyne Secures Monitoring Deal for NEP CCS Project 🏆 ClimeFi provides access to CDR portfolio o...

Company Announcements

-

Zero Petroleum seeks North American site for next synthetic fuels production hub, expanding its global network of fossil-free energy innovationTuesday, June 3rd 2025, 4:03 AM CDT Zero Petroleum is...

-

Avina to Develop Nation’s First On-Site SAF Production Facility at Pittsburgh International Airport

Pittsburgh International Airport and Avina Partner to Launch First On-Airport SAF Facility in U.S. Pittsburgh International Airport (PIT) and Avina Synthetic Aviation Fuel (Avina) are partnering t...

-

Epson to Launch Copier-sized Carbon Capture Device by 2028

Seiko Epson develops compact carbon capture unit for industrial emissions Seiko Epson, the Japanese electronics company, is developing a small carbon capture unit roughly the size of an office pri...

-

This initial strategic partnership aims to accelerate the large-scale commercialization of METAGENE™ green hydrogen production systems in response to rapidly growing market demand MONTREAL and LYO...