Tackling Carbon Emissions Through Collaboration

Frontier Carbon Solutions is making bold moves in the carbon capture space with Project Sprint, a new initiative aimed at reducing emissions across the agricultural and refining sectors. The company is partnering with multiple Midwest refineries to capture and store over 400,000 metric tons of CO2 annually.

The plan involves using liquefaction capture technology, which extracts CO2 from fermentation processes at a purity level of more than 90%. It’s a highly efficient system and a strategic choice for biogenic CO2, especially in industries where fermentation is core to operations.

Once captured, the CO2 will be liquefied and transported using existing rail infrastructure—a smart move that limits environmental disruption and avoids building out new logistics networks from scratch.

>> RELATED: Frontier Carbon Solutions Announces the Sweetwater Carbon Storage Hub in Southwestern Wyoming

A Practical, Scalable Carbon Capture Model

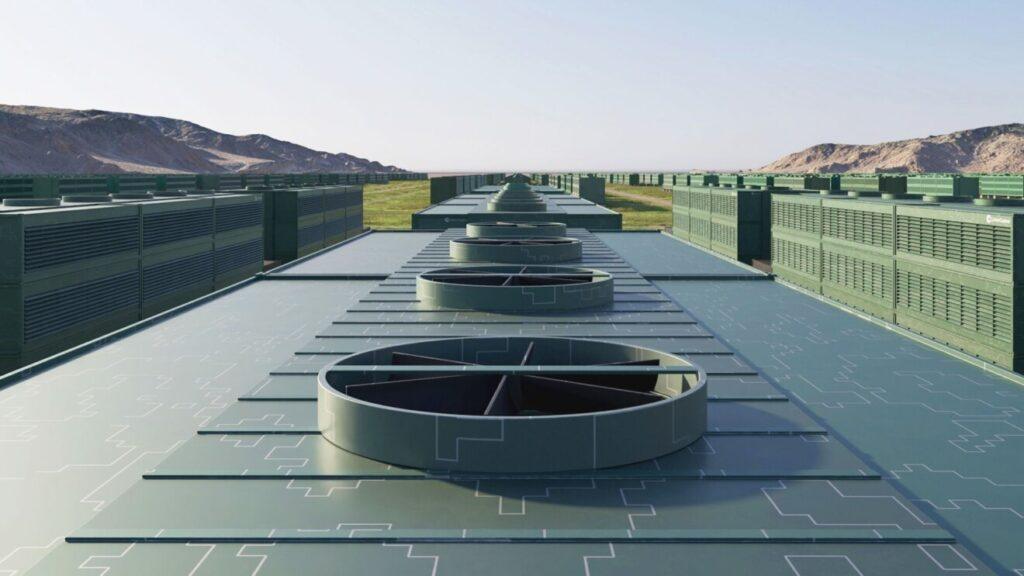

The liquefied CO2 will be shipped to the Granger Carbon Terminal, a CO2 rail offloading hub currently being built by Frontier. From there, it will travel via a dedicated two-mile pipeline to a permanent injection site for underground storage.

This short transport distance from terminal to injection site is part of Frontier’s smart design to streamline carbon storage with minimal impact on surrounding landowners and ecosystems.

By using established rail lines, Frontier avoids the typical conflicts that come with lengthy pipeline builds, especially in areas with dense agricultural activity. This is particularly beneficial for farmers and landowners wary of invasive construction.

Why Project Sprint Matters

Carbon transport across state lines remains a logistical challenge for many companies trying to meet 2030 climate goals. Project Sprint offers a real-world, workable model that could help similar industries follow suit.

“This initiative is one of the few viable solutions for transporting large quantities of CO2 across state lines for storage before 2030,” Frontier noted in its release. The urgency is clear: companies need functional strategies now—not theoretical ones later.

Project Sprint fits into a bigger picture for Frontier, which is leaning heavily into Carbon Dioxide Removal (CDR) technologies to keep momentum going. The company has already earned attention for its work in Wyoming, where it received the first three Class VI permits —a major regulatory step for CO2 storage.

>> In Other News: NewHydrogen Joins Texas Hydrogen Alliance Committed to Accelerate Green Hydrogen Deployment

Frontier’s Growing Network

The Granger Carbon Terminal isn't just a project—it’s becoming a central node in Frontier’s expanding infrastructure. The ability to offload CO2 from rail cars and send it directly to storage makes the terminal a key part of the carbon supply chain.

By housing storage and offloading functions in the same area, Frontier shortens the route from capture to containment. That’s a big deal for industries that need fast, efficient compliance solutions without massive upfront investment.

“Frontier’s strategy is both scalable and practical, designed to deliver quick results,” the company emphasized.

Biogenic CO2: A Crucial Decarbonization Opportunity

The CO2 being captured in this project comes primarily from fermenters, which means it’s biogenic CO2—a type produced during natural biological processes. It’s different from CO2 that comes from burning fossil fuels, and it's becoming a major focus area for carbon capture.

Agriculture and food processing industries have long struggled with how to decarbonize without compromising productivity. This project gives them a real option. That’s why Project Sprint is seen as a potential game-changer for sectors where emissions come from unavoidable biological activity.

Supporting Farmers and Local Communities

One of the most thoughtful aspects of Frontier’s approach is its attention to how carbon projects affect the people who live near them. By relying on existing rail systems and keeping the pipeline distance short, Frontier avoids cutting through farmland or disrupting daily operations for growers.

For many farmers, this kind of project is a welcome alternative to more invasive infrastructure. It reduces emissions without adding stress to the land or requiring long negotiations over easements.

This approach also builds goodwill—something often missing from industrial-scale carbon projects. By keeping things simple and local, Frontier makes it easier for communities to say yes to carbon capture.

Focused on the Midwest, But with Broader Implications

While the partnership centers on Midwest refineries, the strategy Frontier is using could be applied across North America. Leveraging rail and short pipelines isn’t just practical—it’s replicable.

Companies dealing with regulatory hurdles or local resistance to long pipeline corridors may look at this as a blueprint. The project balances technology, regulation, and community sensitivity in a way that’s both rare and promising.

With Project Sprint, Frontier isn’t just cutting emissions—it’s redefining what realistic carbon removal at scale can look like in the U.S.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

Hydrogen Just Got a Major Green Light from the Feds

Inside This Issue ⚡ Energy Department Removes Barriers for American Energy Producers, Unleashing Investment in Domestic Hydrogen 🛳️ MASH Makes Powers First Vessel Trial With Biofuel From a Carbon-...

-

Conestoga Energy Completes Drilling of Class VI Carbon Capture & Sequestration Well, Advances Toward EPA Application

Inside This Issue 🛢️ Conestoga Energy Completes Drilling of Class VI Carbon Capture & Sequestration Well, Advances Toward EPA Application 🏗️ How Microsoft and Sublime Systems Are Reinventing C...

-

EDF Slams 45V Hydrogen Credit Repeal Over $32B Cost, Job Losses

Inside This Issue 💸 EDF Slams Repeal of 45V Hydrogen Credit, Citing $32Bn in Higher Household Energy Costs and Job Losses 🤝 Johnson Matthey to Sell Blue Hydrogen Business to Honeywell as Part of £...

Company Announcements

-

The U.S. Department of Energy’s (DOE) Hydrogen and Fuel Cell Technologies Office today removed barriers for the American hydrogen industry by updating its 45VH2-GREET modeling tool. The latest vers...

-

NETL Patents New Process for Extracting Critical Resources from Coal Fly Ash at High Quantities

NETL researchers developed a new process for extracting economically and strategically vital rare earth elements (REE) and critical minerals (CM) from America’s coal fly ash at high quantities and ...

-

World’s First Plant That Captures CO2 From Air to Make Building Materials Opens

Aggregates produced using CO2 captured by Mission Zero Technologies ‘Direct Air Capture’ technology (Image courtesy of Mission Zero Technologies) A demonstration project that uses direct air captu...

-

Plug Power’s Georgia Hydrogen Plant Sets U.S. Production Record Using Plug Electrolyzer Technology

April 2025 Marks Industry-Leading Milestone with 300 Metric Tons of Liquid Hydrogen Produced WOODBINE, Ga., -- Plug Power Inc. (NASDAQ: PLUG), a global leader in comprehensive hydrogen solutions, ...