A new path for concrete, with seawater and science

Concrete's dirty secret is out. Depending on who you ask, it accounts for 5% to 10% of the world’s carbon emissions. But a team of researchers at Northwestern University says it doesn’t have to be that way — and they’ve come up with a radical solution.

Working with global building materials company Cemex, the Northwestern Engineering team has developed carbon-negative concrete. Not just "less bad" — actually carbon-removing. And they’re not stopping with just concrete. This same approach could change how we make cement, paint, and plasters.

>> RELATED: Demand For Low-Carbon Cement Is On The Rise

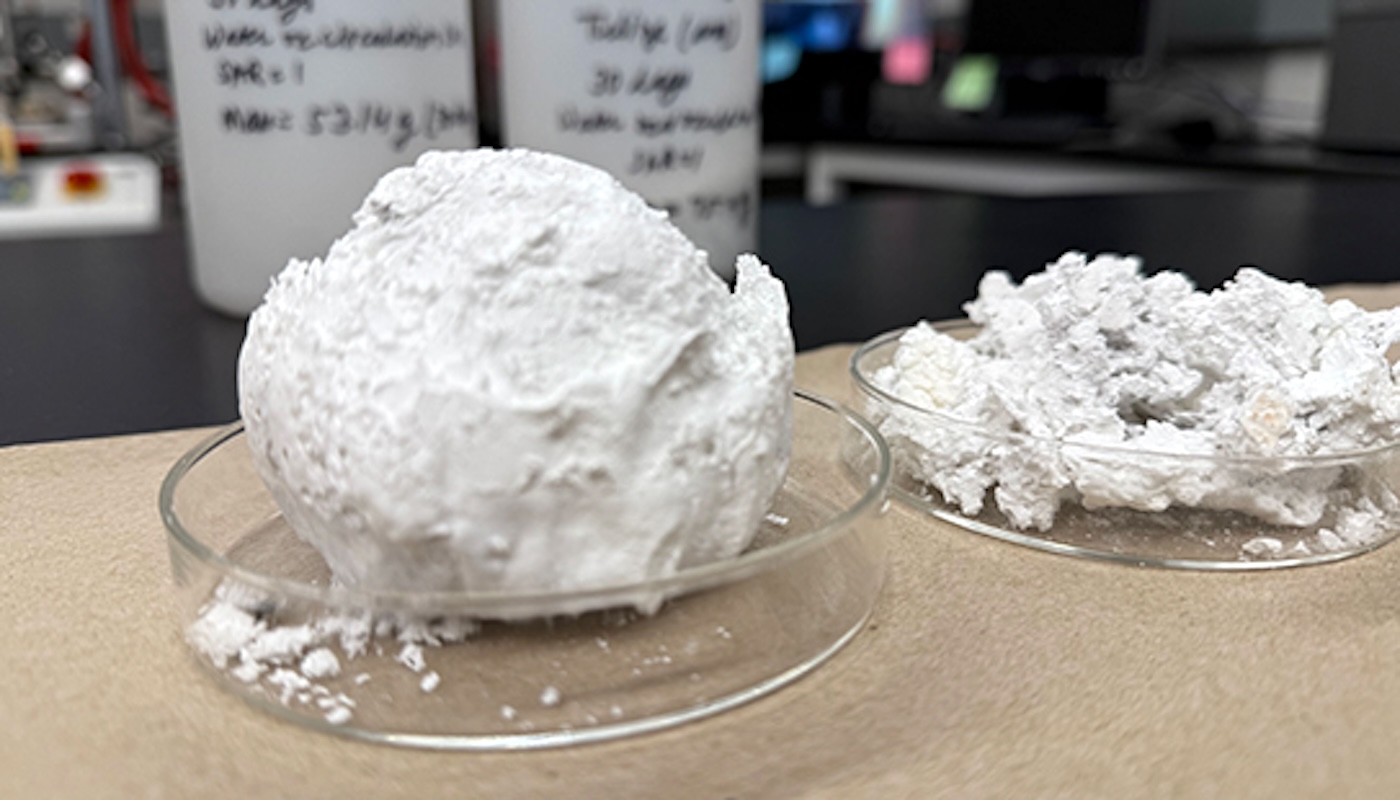

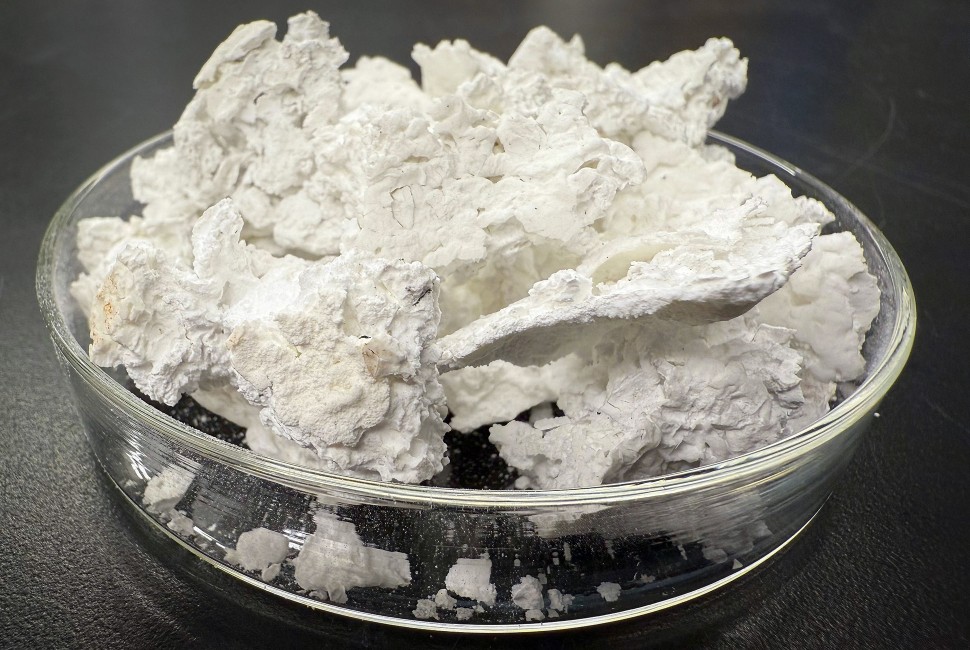

Carbon-negative materials; via Northwestern University.

What makes this tech different?

Unlike traditional cement-making, which releases huge amounts of CO2, the new process developed by Dr. Alessandro Rotta Loria and his team flips the script.

“We have developed a new approach that allows us to use seawater to create carbon-negative construction materials,” said Dr. Alessandro Rotta Loria, PhD, a faculty member at Northwestern.

Instead of mining for raw sand, the team grows sand-like minerals in seawater, using CO2 and electricity. They insert electrodes into seawater and apply a low electrical current. That current splits water into hydrogen gas and hydroxide ions, and when CO2 is bubbled in, the reaction creates calcium carbonate and magnesium hydroxide — both solids.

The result? Materials that behave like concrete but lock away CO2 — potentially for centuries.

Concrete made like coral?

The scientists say their process mimics how corals and mollusks form shells. But instead of relying on biology, the system uses electricity to jump-start mineral formation.

The outcome is a sustainable and scalable way to build — without the carbon baggage.

“The appeal of such an approach is the attention that is being given to the ecosystem and using science to harness the elements in the contemporary environment to develop valuable products for several industries and preserve resources,” said Davide Zampini, vice president of global R&D at Cemex.

That’s a big statement coming from a company responsible for massive volumes of traditional cement production.

Carbon-negative material forming around electrodes

>> In Other News: Innovating the Future: Gautam Swami's Global Journey in Low-carbon Energy and Finance

A partnership grounded in science and scale

The real power of this development lies in who’s backing it. Cemex, a global leader in ready-mix concrete, isn’t just watching from the sidelines. They’re collaborating with Northwestern to make this tech practical and ready for commercial use.

This means the innovation won’t just sit in a lab journal. It could end up in real-world buildings, roads, and infrastructure sooner than we think.

And with Cemex recently named one of the world’s most ethical companies, the timing aligns with its public push for more sustainable materials.

Why sand matters too

What might surprise many is how big of an issue sand mining has become. It’s been quietly wreaking havoc on riverbeds, coasts, and ocean floors around the world. By making a synthetic alternative using seawater and CO2, the new method also offers a fix for a less-publicized environmental crisis.

One top comment on the announcement sums it up well:“Solving two problems with one solution is fantastic.”

Bigger than concrete

While the focus has been on concrete, the potential reach of this technology is broader. The same process could apply to paint, plasters, and even new kinds of carbon-storing construction materials. That means entire buildings could one day serve as carbon sinks, not just shelters.

This builds on earlier work from Dr. Rotta Loria’s lab, which found a way to store CO2 in concrete long-term, without compromising its strength.

That’s key for mass adoption — no one wants to sacrifice performance for sustainability, especially in construction.

What's next?

With proven lab results and an eager commercial partner, all eyes are on the next steps. Scaling this innovation will require investment, new supply chains, and regulatory approvals.

But the urgency is real. Just lowering emissions won’t be enough anymore. As climate change accelerates, the goal is shifting to removing carbon from the atmosphere.

This kind of material could help tip the scales — not just stop the damage, but actually reverse it.

A meaningful step forward

For years, climate solutions have circled around cutting emissions. But we’re past that stage now. We need ways to pull carbon out of the atmosphere, and this Northwestern-Cemex collaboration is a step in that direction.

It’s not just about fixing concrete. It’s about fixing what concrete represents: the foundation of modern life, and, potentially, a tool for healing the planet.

And if we can build cities that remove carbon instead of adding it? That’s a blueprint worth following.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

Hydrogen Just Got a Major Green Light from the Feds

Inside This Issue ⚡ Energy Department Removes Barriers for American Energy Producers, Unleashing Investment in Domestic Hydrogen 🛳️ MASH Makes Powers First Vessel Trial With Biofuel From a Carbon-...

-

Conestoga Energy Completes Drilling of Class VI Carbon Capture & Sequestration Well, Advances Toward EPA Application

Inside This Issue 🛢️ Conestoga Energy Completes Drilling of Class VI Carbon Capture & Sequestration Well, Advances Toward EPA Application 🏗️ How Microsoft and Sublime Systems Are Reinventing C...

-

EDF Slams 45V Hydrogen Credit Repeal Over $32B Cost, Job Losses

Inside This Issue 💸 EDF Slams Repeal of 45V Hydrogen Credit, Citing $32Bn in Higher Household Energy Costs and Job Losses 🤝 Johnson Matthey to Sell Blue Hydrogen Business to Honeywell as Part of £...

Company Announcements

-

The U.S. Department of Energy’s (DOE) Hydrogen and Fuel Cell Technologies Office today removed barriers for the American hydrogen industry by updating its 45VH2-GREET modeling tool. The latest vers...

-

NETL Patents New Process for Extracting Critical Resources from Coal Fly Ash at High Quantities

NETL researchers developed a new process for extracting economically and strategically vital rare earth elements (REE) and critical minerals (CM) from America’s coal fly ash at high quantities and ...

-

World’s First Plant That Captures CO2 From Air to Make Building Materials Opens

Aggregates produced using CO2 captured by Mission Zero Technologies ‘Direct Air Capture’ technology (Image courtesy of Mission Zero Technologies) A demonstration project that uses direct air captu...

-

Plug Power’s Georgia Hydrogen Plant Sets U.S. Production Record Using Plug Electrolyzer Technology

April 2025 Marks Industry-Leading Milestone with 300 Metric Tons of Liquid Hydrogen Produced WOODBINE, Ga., -- Plug Power Inc. (NASDAQ: PLUG), a global leader in comprehensive hydrogen solutions, ...