IperionX Achieves First UL Validated 100% Recycled Titanium

Published by Todd Bush on June 15, 2023

CHARLOTTE, N.C.--(BUSINESS WIRE)--IperionX Limited (NASDAQ: IPX, ASX: IPX), a leader in titanium metal production, is pleased to announce it has achieved the UL Environmental Claim Validation Procedure 2809 for its 100% recycled, low-carbon titanium metal powder.

UL Solutions (UL) is a global leader in sustainability standards, and IperionX’s low carbon titanium is the first commercial titanium metal powder for additive manufacturing to achieve UL validation for 100% recycled content.

>> In Other News: Chart and Kathairos Expand Partnership for Methane Emission Reduction Technology

UL recycled content validation is important as titanium metal powder for additive manufacturing can only be used a limited number of times before quality is impacted by contaminants or inferior powder morphology. Out-of-specification titanium powder increases the probability of defects which jeopardize the structural integrity of additively manufactured components. Additionally, titanium metal produced by the standard “Kroll Process” is energy intensive, high cost, high carbon and is hindered by low levels of circularity. The current manufacturing process for titanium products generates large volumes of titanium waste that is downcycled to the ferro-titanium market or shipped to landfill.

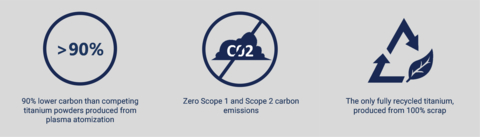

In contrast, IperionX titanium is low-carbon with zero scope 1 and 2 emissions. IperionX can uniquely use 100% scrap titanium as feedstock to produce high performance, low-carbon recycled titanium metal via a circular supply chain that doesn’t rely upon mined resources.

IperionX recently completed a life cycle assessment (“LCA”) for its 100% recycled, low-carbon titanium metal. This LCA confirmed that IperionX’s titanium has the lowest quantified life cycle carbon footprint for commercial titanium powder, with a potential life cycle carbon footprint of just 7.8 kg of carbon dioxide equivalents (“CO2e”) per kg. This forecast carbon footprint is over 90% lower than competing titanium powders produced from plasma atomization, 80% lower than from titanium ingot produced from the Kroll process, more than 50% lower than aluminium ingot, and near equal to stainless steel ingot1. Further details and a copy of IperionX’s LCA can be accessed here.

Notably, IperionX recently won the U.S. Air Force Research Laboratory Grand Challenge to produce high quality titanium metal powder from only titanium scrap feedstocks. IperionX successfully overcame a field of leading titanium companies to produce low-carbon 100% recycled titanium metal from titanium scrap or out-of-specification titanium powder feedstocks.

Major companies across the automotive, defense, bicycle, consumer electronics and green hydrogen sectors desire low carbon titanium from traceable recycled sources to meet their sustainability targets. Materials selection is an important way for manufacturers to reduce the carbon intensity of their products and yet meet demanding requirements for durability, quality and performance. IperionX offers these companies a unique and valuable solution to maximise recycled content, lower carbon footprints and still produce high performance titanium products.

Anastasios (Taso) Arima, co-founder and CEO of IperionX said:

“We are very pleased to achieve UL validation for IperionX’s 100% recycled titanium powder. This independent validation recognizes the sustainability performance of our titanium versus competing metal products. In combination with the results from our Life Cycle Assessment, UL validation indicates that IperionX has the lowest carbon, 100% recycled titanium metal on the market.”

About UL Solutions

UL Solutions delivers testing, inspection and certification services, together with software products and advisory offerings. The UL Marks serve as a recognized symbol of trust in their customers’ products and reflect an unwavering commitment to advancing UL’s safety and sustainability mission.

About IperionX

IperionX’s mission is to be the leading developer of low-carbon titanium for advanced industries including space, aerospace, electric vehicles and 3D printing. IperionX’s breakthrough titanium technologies can produce titanium products that are low carbon and fully circular. IperionX is producing titanium metal powders from titanium scrap at its operational pilot facility in Utah and intends to scale production at a Titanium Demonstration Facility in Virginia. IperionX holds a 100% interest in the Titan Project, which has the largest JORC compliant resource of titanium, rare earth and zircon rich mineral sands in the U.S.A.

>> RELATED: IperionX Plans to Build the World’s Largest 100% Recycled Titanium Metal Powder Facility By 2025

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

What Do Submarines Have to Do With Hydrogen?

Inside This Issue 🚢 Hyundai Pitches Hydrogen Transport Tied To Canada Submarine Bid 🧱 The LEGO Group Expands Its Portfolio Of Carbon Removal Solutions 🏆 SAF Pioneer LanzaJet Honored With RFA Indus...

-

This $4.1M Deal Could Change Carbon Capture's Playbook

Inside This Issue 🗜️ CarbonQuest Lands $4.1M Alberta Deal on Gas Compressors 🛡️ CADO, 123Carbon, and Assure SAF Registry Join Forces to Tackle SAF Integrity Gaps ✈️ ISCC, OMV, and Airbus Partner t...

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

Company Announcements

-

CHIFENG, China, Feb. 27, 2026 /PRNewswire/ -- Envision Energy launched the first global shipment of green ammonia from Chifeng, Inner Mongolia to LOTTE Fine Chemical, a premier chemical company in ...

-

SAF Pioneer LanzaJet Honored With RFA Industry Award

Pioneering sustainable aviation fuel producer LanzaJet received the Renewable Fuels Association’s 2026 Industry Award at the National Ethanol Conference in Orlando this week. Last year the company ...

-

Houston Hosts World Hydrogen North America 2026 Industry Gathering

Hydrogen is one of the energy sources that has evolved the most when it comes to how developers plan and execute projects. The main reason for this is the advanced technology that has penetrated th...

-

Trump EPA Eyes Reallocating Waived Biofuel Obligations To Refiners: Report

The question of whether to reallocate those exempted blending obligations to larger refiners is a point of contention between the agriculture and fuel industries The Trump administration has settl...