.jpg)

New Low-cost Catalyst Helps Produce Environmentally Sustainable Hydrogen From Water

Published by Todd Bush on June 6, 2023

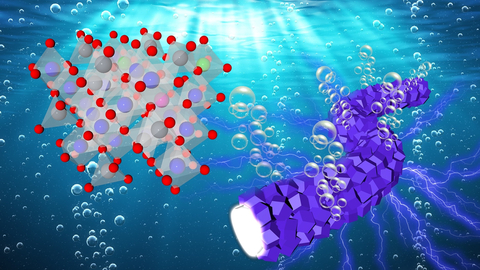

LEMONT, Ill.--(BUSINESS WIRE)--A team led by the U.S. Department of Energy’s (DOE) Argonne National Laboratory has developed a new catalyst composed of elements abundant in the Earth. It could make possible the low-cost and energy-efficient production of hydrogen for use in transportation and industrial applications. Clean hydrogen could not only propel vehicles with no emitted pollutants but also help decarbonize industrial processes.

Other contributors to the project include DOE’s Sandia National Laboratories and Lawrence Berkeley National Laboratory, as well as Giner Inc.

hydrogen from water

>> In Other News: Labor Calls on Governor, Legislature to Invest in Hydrogen Infrastructure

Proton exchange membrane (PEM) electrolyzers represent a new generation of technology for hydrogen production. They can split water into hydrogen and oxygen with high efficiency at near room temperature. The reduced energy demand makes them an ideal choice for producing clean hydrogen by using renewable but intermittent sources, such as solar and wind.

This electrolyzer runs with separate catalysts for each of its electrodes (cathode and anode). The cathode catalyst yields hydrogen, while the anode catalyst forms oxygen. A problem is that the anode catalyst uses iridium, which has a current market price of around $5,000 per ounce. The lack of supply and high cost of iridium pose a major barrier for widespread adoption of PEM electrolyzers. The main ingredient in the team’s new catalyst is cobalt, which is substantially cheaper than iridium.

Giner Inc., a leading research and development company working toward commercialization of electrolyzers and fuel cells, evaluated the new catalyst using its PEM electrolyzer test stations under industrial operating conditions. The performance and durability far exceeded that of competitors’ catalysts.

The team’s achievement is a step forward in DOE’s Hydrogen Energy Earthshot initiative, which mimics the U.S. space program’s “Moon Shot” of the 1960s. Its ambitious goal is to lower the cost for green hydrogen production to one dollar per kilogram in a decade. Production of green hydrogen at that cost could reshape the nation’s economy. Applications include the electric grid, manufacturing, transportation and residential and commercial heating.

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

What Do Submarines Have to Do With Hydrogen?

Inside This Issue 🚢 Hyundai Pitches Hydrogen Transport Tied To Canada Submarine Bid 🧱 The LEGO Group Expands Its Portfolio Of Carbon Removal Solutions 🏆 SAF Pioneer LanzaJet Honored With RFA Indus...

-

This $4.1M Deal Could Change Carbon Capture's Playbook

Inside This Issue 🗜️ CarbonQuest Lands $4.1M Alberta Deal on Gas Compressors 🛡️ CADO, 123Carbon, and Assure SAF Registry Join Forces to Tackle SAF Integrity Gaps ✈️ ISCC, OMV, and Airbus Partner t...

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

Company Announcements

-

CHIFENG, China, Feb. 27, 2026 /PRNewswire/ -- Envision Energy launched the first global shipment of green ammonia from Chifeng, Inner Mongolia to LOTTE Fine Chemical, a premier chemical company in ...

-

SAF Pioneer LanzaJet Honored With RFA Industry Award

Pioneering sustainable aviation fuel producer LanzaJet received the Renewable Fuels Association’s 2026 Industry Award at the National Ethanol Conference in Orlando this week. Last year the company ...

-

Houston Hosts World Hydrogen North America 2026 Industry Gathering

Hydrogen is one of the energy sources that has evolved the most when it comes to how developers plan and execute projects. The main reason for this is the advanced technology that has penetrated th...

-

Trump EPA Eyes Reallocating Waived Biofuel Obligations To Refiners: Report

The question of whether to reallocate those exempted blending obligations to larger refiners is a point of contention between the agriculture and fuel industries The Trump administration has settl...