Powered By SMR From NuScale Power, Utah State University And US National Labs To Advance Ammonia Process Innovations

Ammonia production via the Haber-Bosch (H-B) process was one of the most impactful inventions of the 20th century. It is a challenging chemical reaction that converts hydrogen and nitrogen into ammonia. Approximately 170 million tons of ammonia are produced annually to meet global agricultural needs.¹ Currently, the conventional ammonia production process relies on natural gas steam reforming for hydrogen production, which leads to significant greenhouse gas emissions. It is estimated that ammonia production alone accounts for over 420 million tons of CO₂ annually and 2% of global fossil energy use.² To address this environmental challenge, alternative approaches such as renewable² or nuclear-powered³ water electrolysis are being developed for carbon-free ammonia production.

Putting Principle Into Practice

While simple in principle, splitting water is an energy-intensive process that requires a substantial amount of electricity. One way to decrease the electricity demand is by using high-temperature steam electrolysis (HTSE).⁴ When electrolysing steam, the heat of vaporisation is provided by thermal instead of electrical energy. Thus, ammonia production presents an opportunity for nuclear energy, especially for small modular reactors (SMR), as they serve as a reliable source of heat and electricity.

As a result, the overall economics of carbon-free ammonia powered by nuclear energy can be improved significantly. Being an exothermic reaction under high temperatures, the H-B process can also be integrated with the HTSE system in providing the latent heat of vaporisation for its feed water and improving the overall system efficiency.

Developing An Integrated Approach

Funded by the U.S. Department of Energy under the Nuclear Energy University Program (NEUP), this project will develop two reference designs of carbon-free ammonia plants. One design uses freshwater as the source of hydrogen, while the other design uses seawater (or brackish water). Specifically, the team is focusing on developing innovative system configurations that effectively integrate a SMR with a cryogenic air separation (CAS) unit, a HTSE unit, and a H-B unit. Meanwhile, for the Haber-Bosch process, identifying optimal operating conditions is critical for maximising ammonia conversion yield and the production cost of ammonia. As such, effort has been made to optimise the design/operating conditions of key H-B processes, including the emphasis on reaction kinetics in each H-B reactor and the ammonia separation and recycling loop.

Process modelling and simulations are conducted using Aspen Plus to evaluate the system performance of various configurations. To simplify the modelling structure for the simulations, hierarchical blocks are employed to model each subsystem. Essentially, the integrated systems aim to produce ammonia with zero carbon emissions while striving for the lowest levelised cost of ammonia.

The Current System

The current nuclear-powered ammonia system is designed to operate with a SMR based on a NuScale Power Module (NPM). The NPM has a thermal power rating of approximately 250 MWt and a gross electrical output of 77 MWe.⁵ For the current model, a single NPM is used, though the system can be scaled to incorporate multiple NPMs. In the current designs, the stack of the HTSE operates at 750°C. Despite significant internal heat recuperation between the feedwater and hydrogen product stream being employed, a large amount of latent heat of vaporisation is needed from external heat sources. One of the focuses of the project is to evaluate various integration configurations for preheating the HTSE feedwater, thus optimising the use of available thermal energy among the subsystems.

Optimisation For Improved Ammonia Production

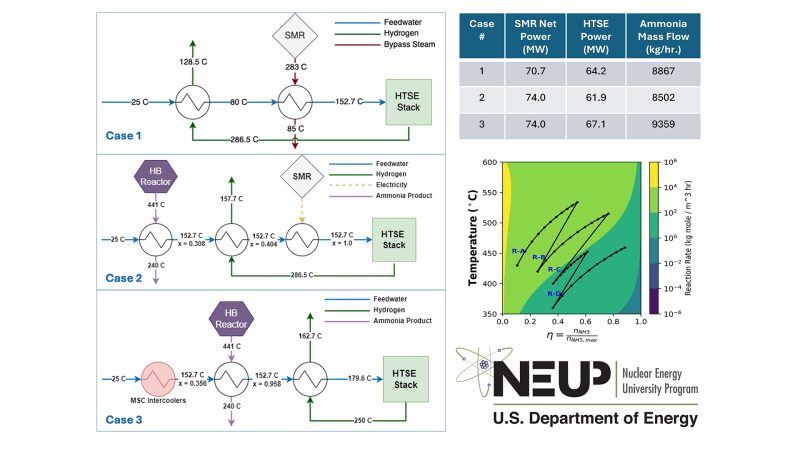

In the preliminary case study, three thermally integrated configurations between the HTSE feed water and the SMR turbine steam and/or H-B ‘waste heat’ as a result of multi-stage compression and exothermic ammonia synthesis reaction have been investigated (see the simplified process diagrams in the figure). Case 1 uses the hydrogen product stream and steam diverted from the SMR to heat the HTSE feedwater until it becomes saturated vapour at 5 bar. The SMR bypass steam flow rate is minimised and exits the heat exchanger at 85°C. Case 2 preheats the HTSE feedwater using ammonia products from the H-B reactor, with the remaining latent heat provided by the hydrogen product stream and an electric heater. Case 3 preheats the HTSE feedwater using the heat generated in the multi-stage compressors (MSC) before receiving additional heating from the ammonia product stream leaving the H-B reactor.

>> In Other News: United Celebrates Turnaround at Newark Liberty International and Charts Bright Future

As shown in the table, more power from the SMR is available for the HTSE system to produce hydrogen in Case 3. As a result, Case 3 has the highest production rate of ammonia by harnessing the waste heat generated in the H-B unit to produce steam for the HTSE. In addition, the figure shows the temperature profile within each of the four H-B reactors, along with the contour plot of the reaction rate as a function of temperature and dimensionless molar fraction of NH3.

While the team is continuing to explore innovative system configurations and perform unit-level design optimisation, the focus will be shifted to perform system-level optimisation and techno-economic analysis (TEA) of the production cost of ammonia. Meanwhile, the project will incorporate freeze desalination and ice energy storage subsystems when using seawater or brackish water as the hydrogen source, further demonstrating the utility and potential impact of the SMR-powered innovative carbon-free ammonia systems.

References

Yüzbaşıoğlu AE, Tatarhan AH, Gezerman AO. Decarbonization in ammonia production, new technological methods in industrial-scale ammonia production and critical evaluations. Heliyon 2021;7. https://doi.org/10.1016/j.heliyon.2021.e08257.

Liu X, Elgowainy A, Wang M. Life cycle energy use and greenhouse gas emissions of ammonia production from renewable resources and industrial by-products. Green Chem 2020;22:5751–61. https://doi.org/10.1039/D0GC02301A.

Lee K, Liu X, Vyawahare P, Sun P, Elgowainy A, Wang M. Techno-economic performances and life cycle greenhouse gas emissions of various ammonia production pathways including conventional, carbon-capturing, nuclear-powered, and renewable production. Green Chem 2022;24:4830–44. https://doi.org/10.1039/D2GC00843B.

Mueller M, Klinsmann M, Sauter U, Njodzefon J-C, Weber A. High Temperature Solid Oxide Electrolysis – Technology and Modeling. Chemie Ingenieur Technik 2024;96:143–66. https://doi.org/10.1002/cite.202300137.

The NuScale Power Module | NuScale Power n.d. https://www.nuscalepower.com/products/nuscale-power-module (accessed September 6, 2025).

Subscribe to the newsletter

Daily decarbonization data and news delivered to your inbox

Follow the money flow of climate, technology, and energy investments to uncover new opportunities and jobs.

Latest issues

-

What Do Submarines Have to Do With Hydrogen?

Inside This Issue 🚢 Hyundai Pitches Hydrogen Transport Tied To Canada Submarine Bid 🧱 The LEGO Group Expands Its Portfolio Of Carbon Removal Solutions 🏆 SAF Pioneer LanzaJet Honored With RFA Indus...

-

This $4.1M Deal Could Change Carbon Capture's Playbook

Inside This Issue 🗜️ CarbonQuest Lands $4.1M Alberta Deal on Gas Compressors 🛡️ CADO, 123Carbon, and Assure SAF Registry Join Forces to Tackle SAF Integrity Gaps ✈️ ISCC, OMV, and Airbus Partner t...

-

Can Koloma Crack Iowa's Billion-Year-Old Secret?

Inside This Issue ⛏️ Iowa's Hydrogen Rush: Can Koloma Strike Gold Before Rules Kick In? ✈️ Bentley Commits to Use 100% Sustainable Aviation Fuel for Car Airfreight 🌬️ Minister Parrott Provides Upd...

Company Announcements

-

CHIFENG, China, Feb. 27, 2026 /PRNewswire/ -- Envision Energy launched the first global shipment of green ammonia from Chifeng, Inner Mongolia to LOTTE Fine Chemical, a premier chemical company in ...

-

SAF Pioneer LanzaJet Honored With RFA Industry Award

Pioneering sustainable aviation fuel producer LanzaJet received the Renewable Fuels Association’s 2026 Industry Award at the National Ethanol Conference in Orlando this week. Last year the company ...

-

Houston Hosts World Hydrogen North America 2026 Industry Gathering

Hydrogen is one of the energy sources that has evolved the most when it comes to how developers plan and execute projects. The main reason for this is the advanced technology that has penetrated th...

-

Trump EPA Eyes Reallocating Waived Biofuel Obligations To Refiners: Report

The question of whether to reallocate those exempted blending obligations to larger refiners is a point of contention between the agriculture and fuel industries The Trump administration has settl...